Micronized Iron Oxide Red 、Micronized Iron Oxide Yellow

Hotline:

- Product description

- Safety data sheet

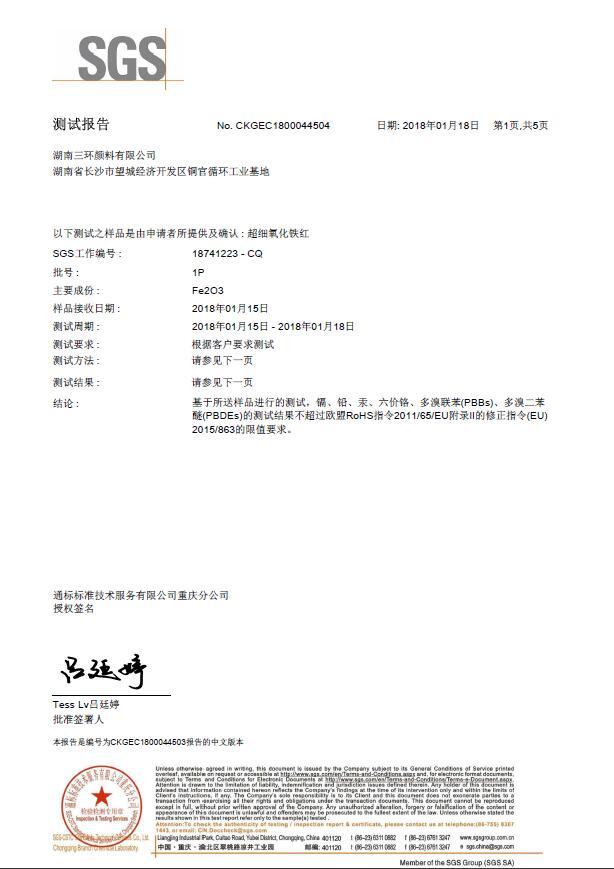

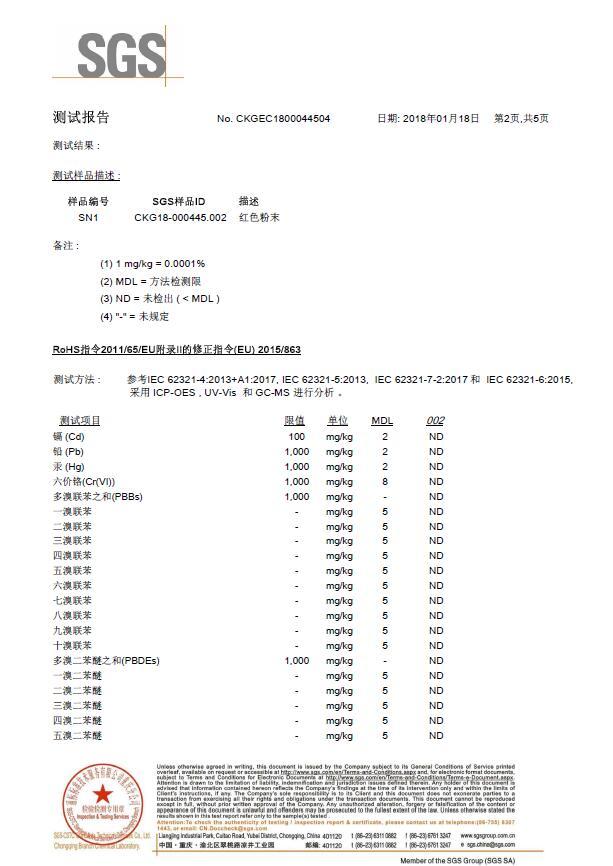

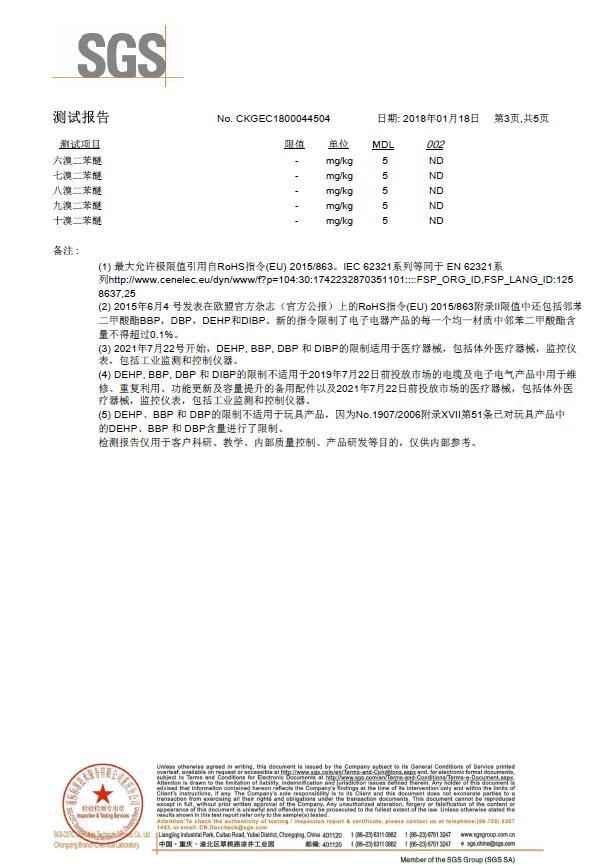

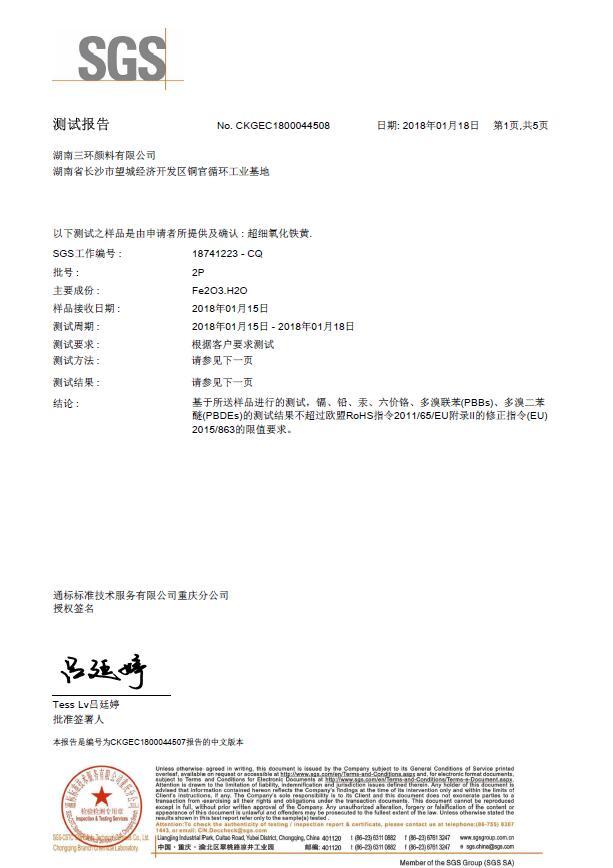

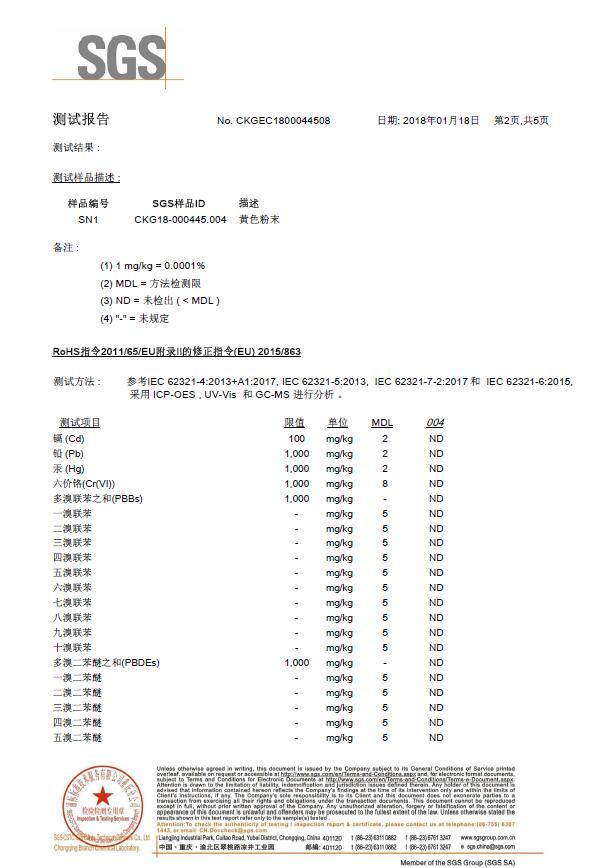

- Product SGS inspection report

-

- Commodity name: Micronized Iron Oxide Red 、Micronized Iron Oxide Yellow

- Commodity ID: 1034761693621477376

The products are mainly used as colorants in high-grade paints, water-based paints, inks, glass, ceramics, plastics, rubber, paper, asbestos, leather, building materials, etc., and can be used as abrasives in machinery because of their good abrasiveness. Used as a catalyst in the chemical industry and as a raw material for the production of other iron-containing products.

§ Main featuresUltra-fine iron oxide pigment is a variety of iron oxide pigments produced by our company by introducing advanced grinding equipment from Germany and adding different additives according to different purposes. The ultrafine iron oxide series pigment not only has the superior performance of general iron oxide pigment, but also the application performance of the product is greatly improved. After processing, the product has no impurities, the fineness D90 is below 1 um, and the coloring strength is increased by 15% to 20%. Different special additives have been added for different purposes, which reduces the surface gravity of the pigment in the medium, makes the pigment easy to grind and disperse, and the storage stability after the paint is greatly improved. The utility model has obtained 7 practical patents. And an invention patent. The products have been exported to many countries and the quality has reached the international advanced level.§ AppearanceIt is powdery and has various types of products such as red and yellow.§ Main ProductsUltrafine pigments: H130M, H110M, H101M, G313M, etc.;§ Product UsageThe products are mainly used as colorants in high-grade paints, water-based paints, inks, glass, ceramics, plastics, rubber, paper, asbestos, leather, building materials, etc., and can be used as abrasives in machinery because of their good abrasiveness. Used as a catalyst in the chemical industry and as a raw material for the production of other iron-containing products.

§ Product ApplicationThe product has good dispersibility, stable storage, good compatibility with other components in the application system, and can enhance the rust and UV resistance of the paint;Paint formula reference pigment amount: primer 25--30%; blend paint 15--30%; enamel 15-25% (excluding body pigment)Water-based paint: Depending on the color, it can be configured in appropriate amount.§ Ultrafine Iron Oxide Pigment Specifications

§ Product ApplicationThe product has good dispersibility, stable storage, good compatibility with other components in the application system, and can enhance the rust and UV resistance of the paint;Paint formula reference pigment amount: primer 25--30%; blend paint 15--30%; enamel 15-25% (excluding body pigment)Water-based paint: Depending on the color, it can be configured in appropriate amount.§ Ultrafine Iron Oxide Pigment SpecificationsNames

Electroferrite Red

Electric iron oxide

Model

Metrics

H130M

H110M

H101M

G313M

Content (minimum %)

95

95

95

86

Color (Max & Delta; E)

Agreed

Agreed

Agreed

Agreed

Tinting strength (% of range)

95~105

95~105

95~105

95~105

Water soluble matter (maximum %)

0.3

0.3

0.3

0.5

Screen residue 325 mesh (45 & mu; m) (maximum %)

0.01

0.01

0.01

0.01

PH value (range)

Agreed

Agreed

Agreed

Agreed

Oil absorption (range g/100g)

Agreed

Agreed

Agreed

Agreed

105 ° C volatiles (maximum %)

1

1

1

1

1000h heat loss at 0.5h (maximum %)

5

5

5

14

Seismic density (g/cm3)

1.0

0.8

1.0

0.5

Density (g/cm3)

4.8

4.8

4.8

4.2

Main particle size μm(range)

0.4

0.3

0.5-0.7

0.1×0.7

Particle shape

Sphere

Sphere

Sphere

Needle shape

§ Ultrafine Pigment Product Color Card:Color Card

Model

Primary colors Light color (TiO2: pigment = 5:1) Iron oxide red H130M

Iron oxide red H110M

Iron oxide red H101M

Iron oxide yellow G313M

Since the actual conditions of use are outside our control, the application data provided by the company is for reference, research and comparison purposes only. Please be sure to apply the test when actually using it. The company has the final interpretation right.Key words:

Since the actual conditions of use are outside our control, the application data provided by the company is for reference, research and comparison purposes only. Please be sure to apply the test when actually using it. The company has the final interpretation right.Key words:- Micronized Iron Oxide Red

- Micronized Iron Oxide Yellow

-

1. Material propertiesThe color is clear and pure, has good pigment characteristics and chemical properties, has high coloring power and hiding power, is excellent in weather resistance and light resistance, is insoluble in alkali, and has stable performance in a certain acidity range, and can be completely dissolved in concentrated hydrochloric acid.Product Chinese name: 超微细氧化铁红、超微细氧化铁黄。English name : Micronized Iron Oxide Red, Micronized Iron Oxide YellowProduct common name: H130M iron red, H110M, H101M, G313M.Main uses of the products: coatings, glass, ceramics, plastics, rubber, cement construction, etc., and because of their good abrasiveness, they can be used as abrasives in machinery.2. Composition/composition information:Ultrafine iron oxide red:Chemical composition: Fe2O3Appearance: red powderIndex number: 77419CAS number: 1309-37-1EEC number: 215-168-2Ultrafine iron oxide yellow:Chemical composition Fe2O3•H2O or FeOOHAppearance: yellow powderIndex number: 77492CAS number: 51274-00-1EEC number: 257-098-53. Risk descriptionDescription of hazards: Not dangerous.A detailed description of the hazards of the substance to humans and the environment: so far the product is not a substance that requires mandatory hazard marking.4. First aid measuresAfter inhaling the substance: Fresh air should be taken immediately.After skin contact with the substance: rinse with soapy water.If the substance is inadvertently ingested: rinse with plenty of water for 10-15 minutes.5. Firefighting measuresExtinguish the fire source in the usual way.Remove nearby dangerous goods, remove their burning residues, and ventilate to remove combustion gas products.No special protection is required.Proper breathing apparatus may be required.6. Accidental leak response measuresReduce pollution to the environment: Do not enter the public facilities, sewers or public areas.Cleaning method/collection: When dust is generated, use a dry brush to clean.7. Storage methodSafe storage method: sealed to prevent dust from entering.Isolated from flammable and explosive materials.The product is not flammable.Store in a cool dry seal at room temperature.8. How to use and personal protectionWorker's protection: Take care to prevent the formation of dust when feeding.Respiratory protection: Wear a dust mask when the product forms dust.Eye protection: Wear eye mask/mask.Body protection: Wear suitable protective clothing.Hand protection: wear protective glovesOther protection: Keep away from food, beverages and tobacco, wash your hands before and after work.9. Physical and chemical propertiesAppearance and traits : red powder and yellow powderColor : Orange Red to Purple Red and Brown YellowOdour : TastelessPH : 3.5-7Relative density : 4.8g/cm3 (ultra-fine iron red), 4.2g/cm3 (ultra-fine iron yellow)Tap density : 0.8-1.1g/cm3 (ultrafine iron red), 0.5g/cm3 (ultra-fine iron yellow)< /div>Related safety data (varies with conditions)Melting point: 1565 °C dissolved)Flash point: UnknownFlammability: UnknownExplosive characteristics: UnknownSaturated steam pressure: unknown10. Stability and reactivityProduct performance is stable,It will not be harmful if handled as required.11. Toxicity dataPractical experience: This product does not pose a hazard to the body, and can be given proper proper treatment and hygiene prevention.12. Ecological dataDo not throw empty bags of product in the sewer or water without treatment,Do not store in a public warehouse.13. Packaging ProcessingContaminated packaging should be thrown into a suitable garbage dump.The contaminated packaging must be emptied of all residues and properly cleaned, and the uncontaminated packaging can be recycled for the next round.14. TransportationThe product is not a hazardous substance,Can be transported on national/international roads, railings, oceans and air.15. RestrictedHazard symbols and hazard indications: no hazard symbols.Additional data: A product that has not been used as a mandatory imprint so far.16. Other dataDetailed information on the existing product data of the department. All data is based on existing theories, and we guarantee that the product does not have any characteristics of dangerous goods and does not affect the establishment of an effective contractual relationship.

-

Micronized Iron Oxide Red

Micronized Iron Oxide Yellow

Micronized Iron Oxide Yellow

Previous

Product recommendation

Widely used as colorants for paint, water-based paint, ink, glass, ceramics, plastics, rubber, paper making, asbestos, leather, tipping paper, printing, adhesive tape color, cement, color asphalt, square floor, floor tiles and other building materials

Reasons for choosing us

Reliable product quality

Strictly control the whole process of production process according to the requirements of ISO9001: 2015 quality management system, use advanced testing instruments in the industry to control product quality according to the requirements of ISO1248:2006 standard, and ensure the consistency of quality and color of each batch of products.

Customizable pigment and processing

Our company's nationwide sales, wholesale, service providers and technical support network provide timely and complete after-sales service for local customers. The laboratory is responsible for the quality inspection of products and the development of new products, constantly meeting the needs of customers in new processes and new applications.

Online Message